This 3D Printer Can Build Ten Houses in a Day Using Recycled Materials

Rahul Kalvapalle — April 24, 2014 — Eco

China-based company Winsun demonstrated the impressive capabilities of its giant 3D printer by using it to construct ten 3D-printed houses in less than 24 hours. The homes are largely constructed out of recycled materials and are cheap enough -- less than $5,000 each -- to be constructed in large quantities to ease housing crises in developing countries.

Each small house takes very little labor to assemble, and costs as little as $4,800. Winsun hopes to make them available for low income housing projects.

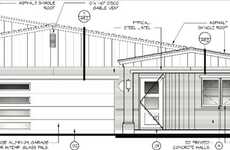

The 3D printer doesn't print the homes in one go, instead creating building blocks by layering a cement-and-glass mix in structural patterns. This allows for a diagonally reinforced print pattern that leaves gaps of air to provide insulation. The blocks are then printed in a central factory and assembled on site.

This efficient, low-cost construction process requires minimal manual labor, opening up possibilities for rapidly 3D-printed houses to be put together to ease housing crises.

Each small house takes very little labor to assemble, and costs as little as $4,800. Winsun hopes to make them available for low income housing projects.

The 3D printer doesn't print the homes in one go, instead creating building blocks by layering a cement-and-glass mix in structural patterns. This allows for a diagonally reinforced print pattern that leaves gaps of air to provide insulation. The blocks are then printed in a central factory and assembled on site.

This efficient, low-cost construction process requires minimal manual labor, opening up possibilities for rapidly 3D-printed houses to be put together to ease housing crises.

Trend Themes

1. Rapid 3D Printing - The ability to 3D print houses in less than 24 hours creates disruptive innovation opportunities for the construction industry.

2. Recycled Materials - The use of recycled materials in 3D-printed houses presents disruptive innovation opportunities for sustainable and eco-friendly building practices.

3. Affordable Housing - The low cost of 3D-printed houses opens up disruptive innovation opportunities for providing affordable housing solutions in developing countries.

Industry Implications

1. Construction - The construction industry can explore disruptive innovation opportunities by integrating rapid 3D printing technology into their processes.

2. Sustainable Building - The use of recycled materials in 3D-printed houses creates disruptive innovation opportunities for the sustainable building industry.

3. Real Estate - The development of affordable 3D-printed houses presents disruptive innovation opportunities for the real estate industry, especially in addressing housing crises.

5.6

Score

Popularity

Activity

Freshness